Machines Parts

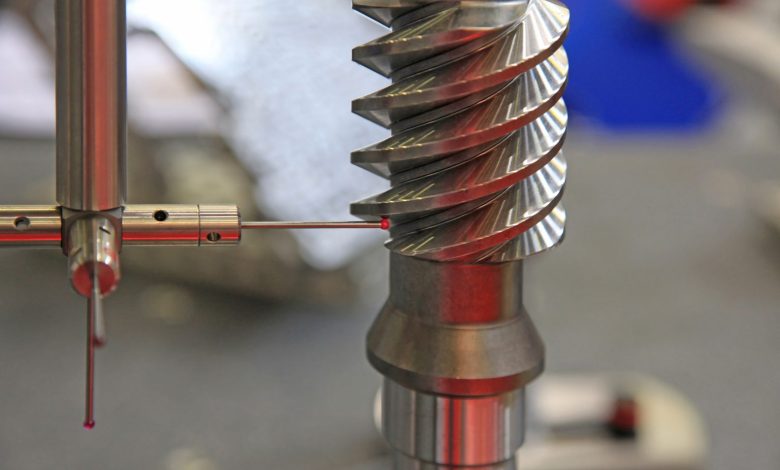

What are machined parts?

Machined parts are everywhere. From tiny metal fasteners to aircraft engine components, all sorts of parts have been built using the process of machining. But what exactly is machining. machined parts & components manufacturer

Why use machined components?

There are many reasons why companies, product designers, R&D departments, and other professionals might use machined parts. And many of the specific advantages of machined parts are described in the following section.

Advantages of machined parts

Machined parts offer certain benefits that may not possible with, for example, injection molded parts or 3D printed parts. Some of the key advantages of machined parts are listed here.

1. No MOQ

One of the principal advantages of machined parts is the ability to purchase them with no minimum order quantity.

For molded parts, it is necessary to fabricate metal tooling — a process that takes a long time and typically costs tens of thousands of dollars. Machined parts, however, are cut directly from a blank workpiece, which makes it cost-effective to order very small quantities or even one-off parts.

2. Good prototypes

Some companies choose to order injection molded prototypes, but it is typically only large companies that can afford to do so. The cost of tooling can make prototyping prohibitively expensive.

Prototypes

Machined parts are suitable and affordable as prototypes because they can be fabricated as one-offs. Machining is also much faster than molding, which means R&D departments can quickly iterate several versions of a part, then put it through whatever testing or assessment is required before moving on to production.

The material versatility of machining also means companies can, for example, order machined parts in several different metal alloys or composite plastics to see which performs best under test conditions.

3. Design freedom

Machined parts can have a wide variety of shapes and sizes. This is because CNC machining is not subject to extreme molding design constraints like thin walls and tapering; machined parts can be thick and robust, but their features can also be fine and detailed.

Machined parts

Although Machined components have some limitations when it comes to, for example, internal sections and deep channels, machining still represents one of the most geometrically flexible manufacturing processes. Molded parts, on the other hand, must have thin walls and conform to more strict design criteria generally.

Even 3D printing, generally seen as one of the best manufacturing techniques in terms of design freedom, has limitations such as avoiding overhangs.

4. Quality

Machined parts can be made to a very high standard. Perhaps more importantly, customers can specify tolerances which need to be met by the machinist. This means the machinist or machine operator can take extra time on tight-tolerance parts and individual features.

Injection molds

While injection molds can also be made to tight tolerances, each individual molding cannot be held to such high standard. Moldings produced toward the end of the mold lifespan may lack the definition of earlier units.

5. Lead times

Machined components can be fabricated faster than parts made via other production processes like molding. This is partly due to the absence of labor-intensive tooling. But the manufacturing process itself is also highly efficient: some of the faster machining centers equipped with linear guide rails have rapid rates of around 4,000 centimeters per minute.

Fastest to fabricate

The one-step nature of machining and the speed of CNC machining centers combine to make machined parts some of the fastest to fabricate. reducing lead times for shorter time-to-market and practical rapid prototyping.

6. Alterations

Because CNC machined parts are made from a digital CAD file, it is possible to make changes to that digital design right up until the moment of fabrication. This is useful during R&D and prototyping when engineers might want to make fractional adjustments to the machined part or create multiple versions. It also reduces the possibility of waste, since defective parts are less likely to make.

Significant advantage

This is a significant advantage for machined parts over molded parts: tooling cannot easily be changed, and it would be a huge waste of money to create a new mold if a last-minute alteration is required.

7. Strength

Machined parts are cut from solid pieces of material known as blanks, which have typically been cast or extruded. This makes them very strong compared to, for example, 3D printed parts, which can be much weaker along one axis where one layer is built upon the next.

Many machined parts are also stronger than their molded equivalents since molded parts must have thin walls and are therefore limited in terms of mechanical performance.

8. Surface finish

Machined parts avoid the surface quality issues associated with molding such as flow lines, jetting, and flash at the parting line. With a moderate amount of post-processing, machined parts can be brought to a very high standard in terms of surface finish.

3D printing

Machining also gives a far superior surface finish to 3D printing, even before any post-processing has been carried out. 3D printing, especially FDM printing, can leave visible layer lines on the surface of the part which must be smoothed over via sanding or chemical treatment. Machined parts do not have these layer lines.

How to design machined components

Fortunately, machined parts are not especially difficult to design — just as long as certain rules are followed. These rules are outlined below.

Undercuts

Undercuts cuts in the workpiece that cannot executed using standard cutting tools

Since cutting tools make e in standard sizes, undercut dimensions should be in whole millimeters to match the tool.

Undercut width can range from 3–40 mm, depending on the cutting tool, with undercut depth up to twice the width.

If undercuts can be avoided altogether, the machined parts can be made much faster and with less effort.

Wall thickness

Contrary to molded parts, which deform if walls are too thick, machined parts cannot handle especially thin walls. Designers should avoid thin walls, or use a process like injection molding if thin walls are integral to the design.

Protrusions

As with thin walls, tall protruding sections are difficult to machine, as the vibrations of the cutting tool can damage the section or result in lower accuracy. A protruding feature should have a height no greater than four times its width.

Cavities, holes, and threads

When designing machined parts, it is important to remember that holes and cavities are dependent on the cutting tools. Cavities and pockets can be machined into a part to a depth of four times the cavity width. Deeper cavities will necessarily end up with fillets — rounded rather than sharp edges — because of the required cutting tool diameter.

Four times

Holes, which are made with drill bits. Should also have a depth of no more than four times the drill bit width. And hole diameters should, where possible. Correspond to standard drill bit sizes. Threads, used to incorporate fasteners like screws, do not need to be deeper than three times the diameter. Larger dimensions are possible with larger machines. But this should discussed with the machinist before fabrication.

Machined components materials

Machined parts can make from many different materials, including metals and plastics.

However, some materials are easier to machine than others. Very hard materials are difficult to penetrate with a cutting tool and may cause the tool to vibrate more . Very soft materials and materials with a very low melting point may deform upon contact with the cutting tool. The most common machined part materials are listed below. Other materials can also be machined upon request to the manufacturer.

Metal:

Aluminum, Steel, Stainless Steel, Magnesium, Titanium, Zinc, Brass, Bronze, Copper.

Machine part surface finishes

Machined parts can be treated after machining in order to alter their surface texture and appearance. Finishes can be either functional or cosmetic.

As-machine:

No surface finish added. This is suitable for many internal, non-cosmetic functional components.

Bead blast:

The bead blasting process involves firing abrasive media at the machined part, leaving it with a matte appearance. The process can adjust to give a specific level of roughness. It may not be suitable for fine features, since bead blasting removes material and therefore affects the geometry of the machined parts.

Anodized:

The electrolytical passivation process of anodization is suitable for aluminum machine parts. creating a scratch-resistant, colorful coating. Type II anodization creates a corrosion-resistant finish; Type III is thicker and creates wear resistance in addition to corrosion resistance.

Powder coated:

During the powder coating process. Powdered paint spray onto the machined part, which is then baked in an oven. This creates a strong, wear-resistant, and corrosion-resistant layer that is more durable than standard paint coatings.

Machine part tolerances

Machine parts can make to tight tolerances. Which may necessary for critical mechanical parts that interact with other components. Looser tolerances may be chosen for prototypes and non-mechanical parts.

Read more: Who Will Be the Top Designers of 2022?