Features Of Automatic Palletizer Machine

Nowadays, warehouse storage presents certain difficulties. This is a lot of work. In addition to warehousing and loading operations, cargo needs careful and accurate storage. This is impossible without neat, reliable packaging, as they can deteriorate automatic palletizer machine.

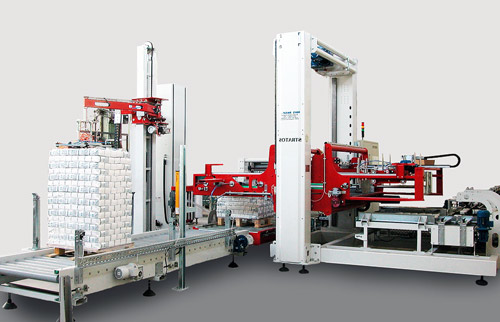

And then palletizers come to the rescue. Palletizers are modern devices that stack loads together and pack them properly. Loads stowed and packed with their help become compact and neat. And since they are closed in several layers, they are protected from external influences. They can be safely stored and transported.

After packing, the goods are transported without loss over long distances and on any transport. So it turns out that palletizers are indispensable equipment for a warehouse. And high automatic palletizer machine demands are placed on them.

Palletizers can be manual and automatic. Manual ones can’t work without a person. A warehouse worker puts layers of packaging on a table, puts a label with a barcode on the packed goods, sometimes sets an empty pallet for packing cargo into it, monitors the movement and operation of the machine. Such equipment can handle bundles of cargo up to 1500 kg and a height of 2500 mm. It costs less than automatic analogs, but when working with it, a specialist is needed. Also, less cargo is packed on it than on an automatic one. This makes it less cost-effective.

The operation of the automatic palletizer is based on cyclicity. The robot manipulator puts layers of cargo on the conveyor, groups them together, covers them with packaging. Beautifully and neatly stacked cargo moves further or moves aside.

Modern palletizers are widely used in industry, pharmaceuticals and logistics.

They greatly simplify the organization of product storage. Time-tested models of automatic palletizers contribute to a significant reduction in costs and an increase in the amount of packaged cargo. With their help, it is quite easy to form a pallet, which consists of several layers. The finished products have a compact and neat appearance and are protected from external factors.

Functional automatic palletizers perform both simple stacking of products and form a multi-layer briquette. They belong to high-performance machines. Thanks to them, it is possible to service several working lines at once, which helps to increase production volumes and speed up all operations carried out. The presented model excludes the human factor, possible errors and inaccuracies. At the same time, all warehouse operations can be carried out without stopping at high speed. Many managers have significantly increased labor productivity due to the introduction of specialized equipment into operation.

Advantages of palletizers in production:

- high productivity due to the maintenance of several lines at once;

- automation of the process eliminates the error due to the human factor;

- flexible software configuration that can be carried out even during the installation process;

- the operating mode can be in several layers, or it can be in the simple stacking mode;

- I work with the packing of goods in cans, bags, boxes and other containers;

- the ability to add other devices and mechanisms;

- the relatively small size of the equipment, which allows you to choose the most optimal placement option

- depending on the lines and products;

- ease of management;

- high operational reliability;

- good hardware documentation.

What is a palletizer?

Specialized equipment that is designed for the formation of pallets. It is used to create multi-layer pallets. Finished products allow rational use of warehouse space. There are both semi-automatic and automatic models. The latter work without the participation of operators. The main advantage of the palletizer for pallets is the ability to lay and move pallets with heavy loads. On average, modern units perform from 10 to 20 cycles per minute.

The automatic robot provides high productivity-900 cycles per hour, serves goods with a load capacity of -700 kg, works for 25 years without replacement. But its work needs to be constantly programmed. At the same time, you can enter new tasks into its program every time. The machine varies the layers of cargo at different levels, works with products of medium and large sizes, regulates the change of the format of packages and performs other programs.

This equipment refers to warehouse equipment, and is used to create pallets, and consisting of several layers. Thus, the products packed on the palletizer have a compact and neat automatic palletizer machine appearance, besides, they are reliably protected from external influences and are fully ready for further use and transportation. Let’s take a closer look at this useful device, its working, and qualitative characteristics and the advantages of using it in this article.

FEATURES OF PALLETIZERS

The palletizer should not be confused with the palletizer, these are completely different devices for their intended purpose, and products are delivered to the palletizer somewhat earlier than to the palletizer. It is the palletizer that forms an absolutely flat rectangle of products, which is already delivered to further packaging in this form. As a rule, this equipment operates in two modes, namely, it performs simple stacking of products and is capable of forming a multilayer briquette.

Undoubtedly, the main advantages of palletizers are their performance characteristics, palletizers are extremely productive machines, the fact is that the equipment of palletizers makes them capable of servicing several working lines at once, so the performance of this device is at a high level. The principle of operation of the palletizer is as follows. On the conveyor platform, which is equipped with a automatic palletizer machine, there is a supply of products that have a common group packaging.

Palletizer

Here it is unpacked and accumulated. After the products accumulate in sufficient quantity, they are automatically moved to the table by a specially designed system. The process takes place in a cyclical order. Then, through the operation of a special mechanism, all products are delivered to a special pallet made of wood, where the laying of laying plates between the layers of products takes place. Further, the products laid in this way are moved aside by means of a mobile conveyor, or by means of loaders for further packaging.

THE DEVICE OF PALLETIZERS

Today, this equipment goes through many upgrades, and can not only be a traditional sliding principle of operation, but also be made in the form of portal machines, as well as have the form of a manipulator robot.

The last type of palletizer has a fully automatic control, which works through software. All processes are performed by such a palletizer independently, from delivery to the table, to movement on pallets, which is performed using a manipulator arm.

The automatic palletizer has several necessary parts.

First of all, there must be means to combine the products and the pallets themselves. This usually involves two or more conveyor belts or moving platforms, but in some cases workers can manually move the pallets to the position manually or using a forklift.

As soon as the palletizer has boxes or barrels and a pallet within reach, it can start its work. The device picks up the product using a crane, manipulator or bucket and carefully puts the box on the pallet. These boxes are usually the same size, but a more advanced robotic tool can be programmed to recognize packages of different sizes and take into account their shape when stacking the pallet.

The palletizer puts boxes or barrels in neat rows, securely packed on a pallet. When the pallet is full, it is either wrapped by the device, or, most often, removed to be wrapped by another machine or manually. Then the palletizer can freely pack the next pallet.

Modern cargo works efficiently with the help of many different machines, not the least of which is the palletizer. Although it may not seem like a device that plays a big role in most people’s lives, every time a person buys a box of cereal, a piece of butter, or a box of spark plugs, this tool probably played an important role in getting it. to the store.